PILOT CASE

VDL Weweler

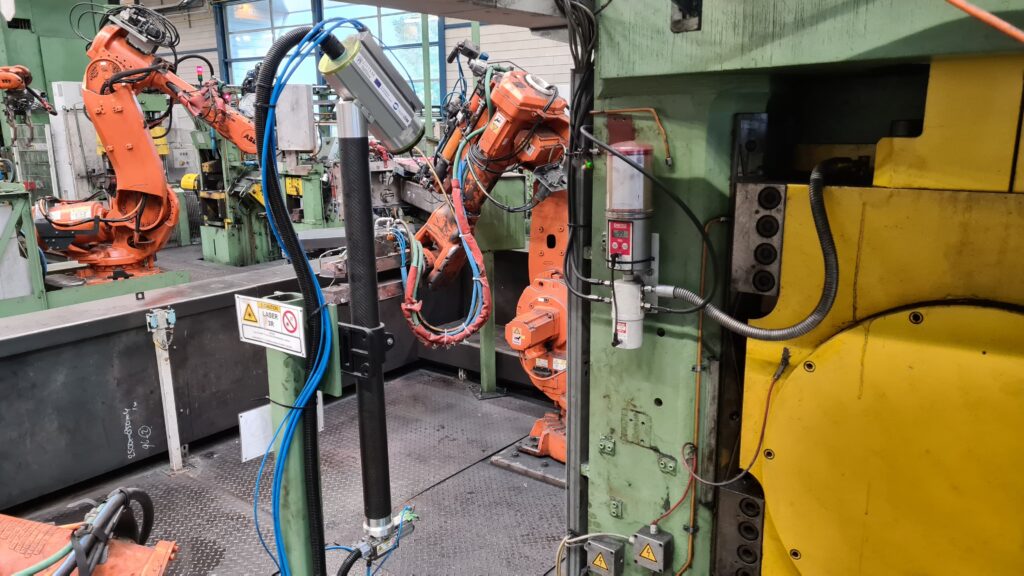

Trailing arm production process demonstrator

In order to overcome identified challenges within the VDL Weweler trailing arm production process this industrial pilot envisages the use of several non-destructive inspection methods and a Digital Twin model of the production process. To keep track of the important production parameters, in real-time, and with the support of AI modules to identify anomalies and adjust the production parameters accordingly.

The proposed approach will allow to adjust the production process to deviations or abnormal patterns ensuring the production of high-quality products while enabling a zero-defect manufacturing process

Pilot Description

Expected Goals

- Gaining more insight into the combined factors that play a role in the occurrence of defects in the products. To then determine to what extent these factors have an influence so that the appropriate actions can be taken. A direct annual waste reduction of 16,2% is expected, downtime is expected to be reduced by 2,2%.

- Automating the measurement of critical dimensional properties and detection of surface defects will eliminate manual actions. The result is an expected annual 790 hours saved in several parts of the production area.

Problem definition

Identified challenges

- Due to the large amount of factors that can influence various possible defects, analysing problems and identifying root causes is a complex process. In order to carry out this process efficiently and effectively, the challenges lie in collecting the correct data and processing this data in such a way that the right connections are made to further optimise the production process.

- In addition, with any changes that are made, the existing production process must continue to meet all strict requirements in order to be able to deliver a continuously high level of quality.

Impact from openZDM technologies

The expected impact of various openZDM technologies to be implemented include reduction of defective products, downtime and elimination of sorting and manual checks.